Acrylic Mirror

Most modern mirrors are made out of one of two materials – silvered glass or mirror acrylic.

They are constructed similarly – silver backing applied to one side of a transparent material (either glass or acrylic). Light enters through the transparent material, and gets reflected back by the silver backing.

Glass mirrors have traditionally been seen as being more luxurious, but as with many things, that doesn’t tell us much about relative merits and pitfalls of the choices. I believe a lot of it comes from the fact that glass is more expensive, and our culture has this silly tendency of seeing more expensive things as being “better”.

In reality, acrylics is superior to glass in many different ways, and inferior to glass in a few ways.

The most significant advantage of glass is scratch-resistance. Glass is much harder than acrylic, and is not nearly as prone to scratches. Glass also last longer, as acrylic has a tendency to turn yellow in the presence of UV over years if used outdoors.

On the other hand, acrylic has 5-10 times the impact strength of glass, while only weighing about half as much. It’s also much cheaper and easier to work with. Mirror acrylic can be cut using a regular 40-80W CO2 laser cutter, while glass should only be cut using water jet cutters, which are much more expensive and not as widely available to hobbyists. Cutting by hand or drilling will require more specialised tools.

They are roughly equal in optical properties when new, and are virtually indistinguishable.

So which one to use depends on what you need the mirror for. In my not so humble opinion, acrylic is more suitable in most cases for functional mirrors, and glass more suitable for mirrors that also double as art, and will be passed down from generation to generation.

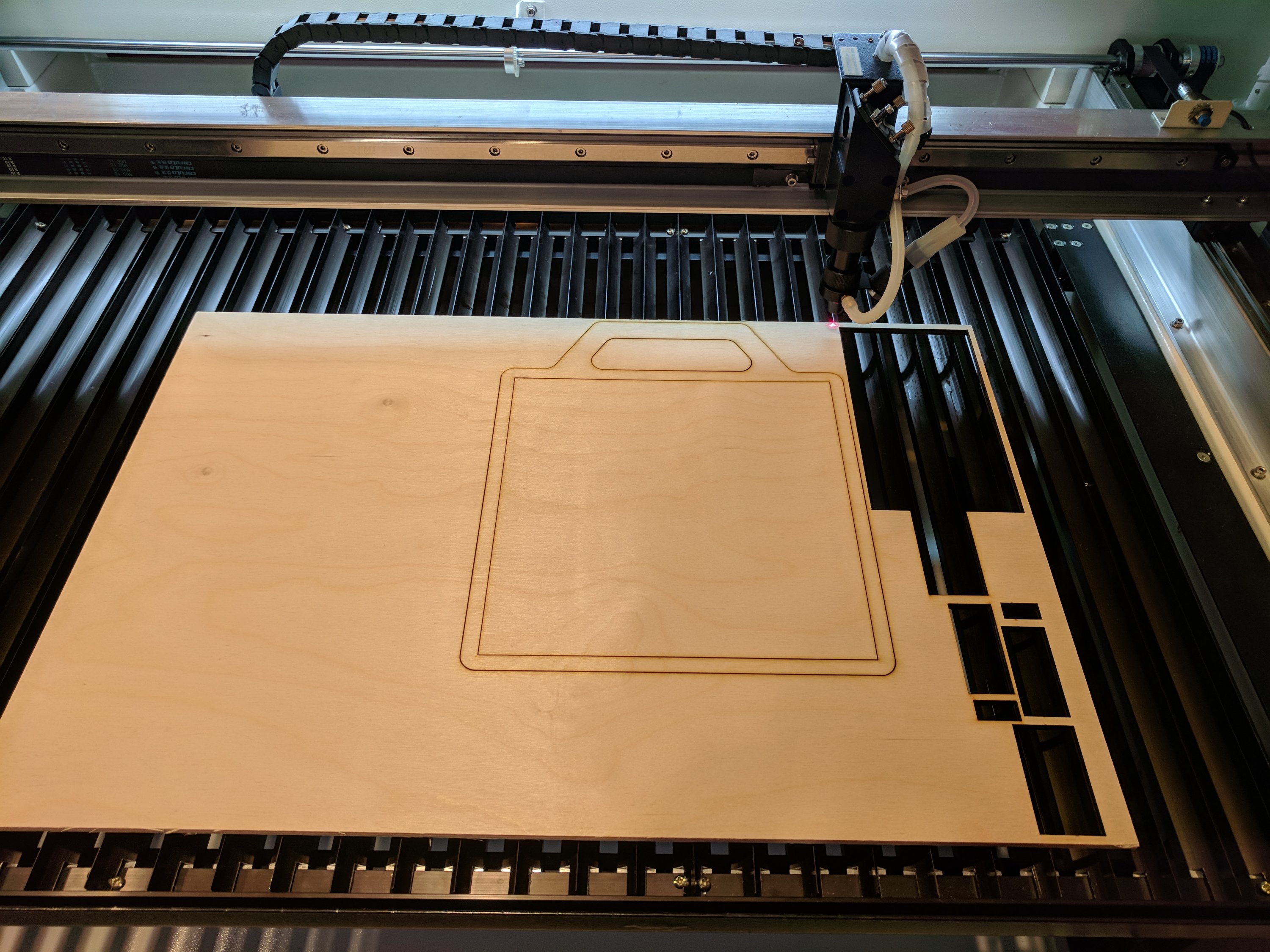

This is a fairly simple project. The mirror was modelled in Autodesk Fusion 360 with the help of my client (my partner, who will use the mirror). Everything was cut on a 80W laser cutter.

Warning: when cutting mirror acrylic, be sure to cut from the non-reflective side! Acrylic doesn’t absorb a lot of energy (about 10% at 900nm, which is what CO2 lasers generate), so almost all the energy will be reflected back to destroy the lenses and mirrors or the laser itself.

The backing is 3mm laser plywood, the mirror is 3mm mirror acrylic, and the border/ridge is 6mm laser plywood to give the acrylic a bit of protection.

The plywood layers were glued together using PVA wood glue, then sanded and oiled. The acrylic is glued to plywood using JB ClearWeld, a fast-setting transparent epoxy.

The end result looked pretty good for such a simple project!

Fusion 360 Render:

Fusion 360 Files: http://a360.co/2ynlcaa